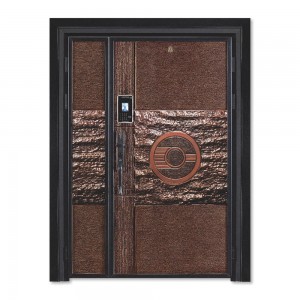

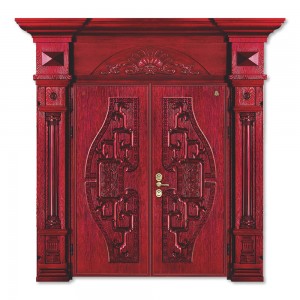

Cast aluminum doors consist only of cast aluminum panels, hot-dip galvanized steel sheets, wood base plates and aluminum profiles, but there are different combinations of different kinds of cast aluminum doors. Commonly, there are solid wood composite cast aluminum doors, double-sided cast aluminum doors and overall casting solid wood cast aluminum doors. Solid wood composite cast aluminum door surface using cast aluminum plate one casting, the thinnest 8mm, no cracking, no deformation, collision resistance, the thickest up to 2-3cm, the border using 2.5mm aluminum profiles wrapped. Double-sided cast aluminum door that the surface and the back are cast aluminum plate, double-sided cast aluminum door using cast aluminum plate for one casting molding cast aluminum plate, the thinnest place 8mm, the thickest place up to 2-3cm, the border using 2.5mm aluminum profile edge.

x

Product Description

Features

Application

Product Parameters

Case Gallery

Write your message here and send it to us